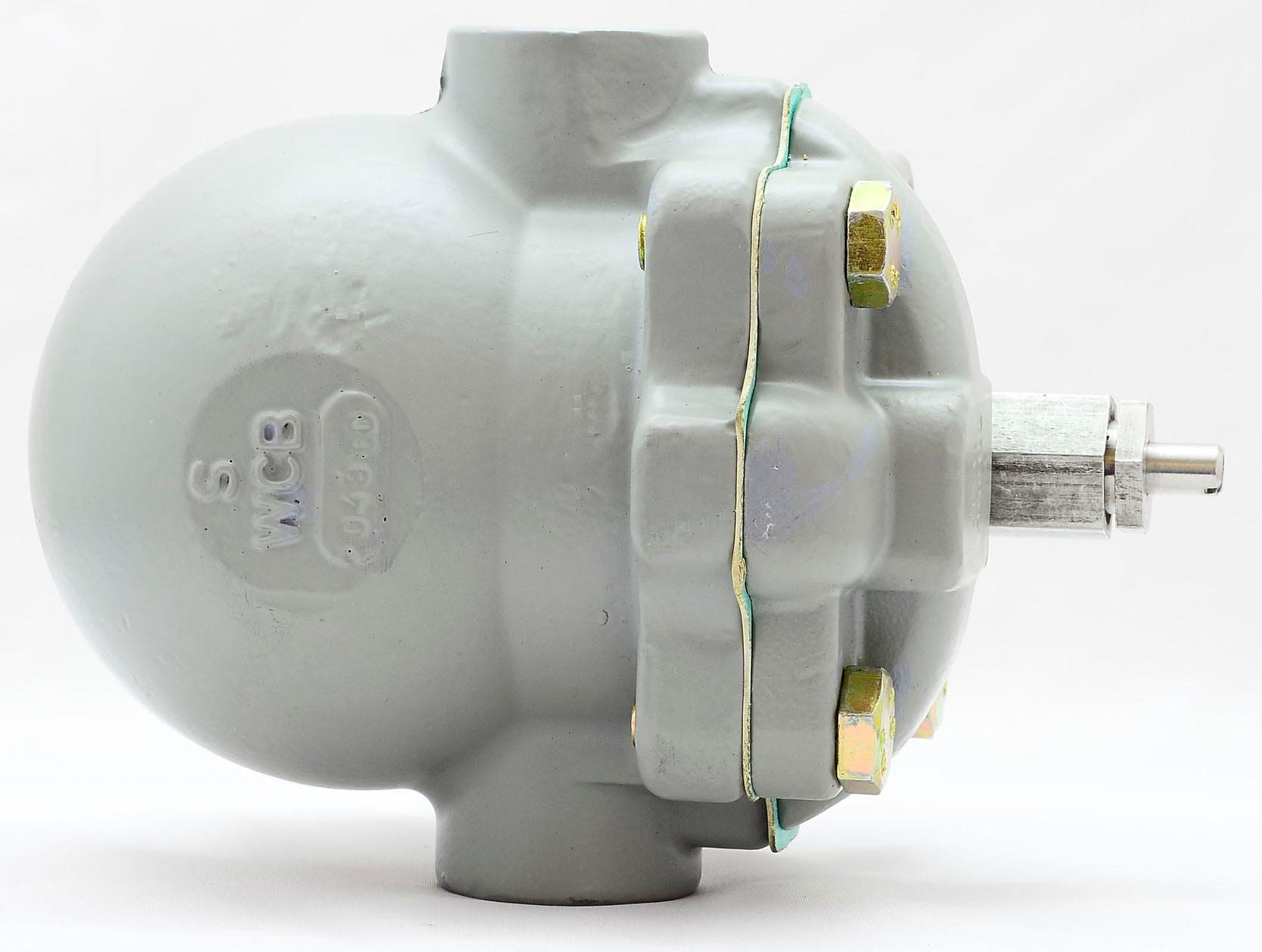

Automatic Pumping Trap

To overcome stalling situation and to enhance the heat transfer efficiency, it is advised to install Automatic Pumping Trap (APT). There are innumerable advantages of installing this device.

APT is a device having the combined features of a conventional steam trap as well as a pump. In situation where the pressure of the condensate approaching APT is suitably high, then the delta pressure inside this APT will facilitate this device to perform as a mere conventional trap only.

However under stalling conditions where the delta pressure inside APT drops below 0.5 kg/cm2(g), this APT is automatically switched over to pumping mode. During this mode, the motive port opens up to allow motive steam to enter in APT resulting in to immediate pumping of the condensate at elevated place.

Advantage of Automatic Pumping Trap –

- Increase in heat transfer capacity & thus reduction in process cycle time

- Appropriate & continuous condensate discharge

- Avoids water hammer

- Avoids corrosion due to cool condensate in batch production processes

- Proper temperature control in process

- Enhanced equipment life

- Reducing the hunting effect of the temperature control valve

- Avoids flashing of hot condensate

- Nil loss of live steam

Ball Float Traps

Steam used for secondary heating like Coils, vessels, heat exchangers etc, generate a lot of condensate post heat transfer. This large quantity of condensate can handle by Ball Float Trap. This condensate has a substantial heat component with cost tagged to it. Also this is treated and pure water and can be used as Feed water for the Boiler, saving the cost of heating, Water Bill and Treatment chemicals. Therefore it makes sense to recycle / reuse this condensate. This function is also done by the Ball Float Trap.

Ball Float Trap discharge condensate near to steam saturation temperature, which works on the principle of Buoyancy, [densities difference of Water and Steam].The rising condensate level elevates the Float open the valve and discharges the condensate, and reverse, when the level of condensate drops, valve close the trap.

The working principle of this trap can also be used as Auto Air Moisture Drain, as Air Eliminator in liquid line, as well as for lifting condensate, as a pump.

- MOC: Cast Iron and Cast Carbon Steel

- Available in Sizes: 15 mm – 50 mm

- End connections: Screwed/Socket weld ends, Flanged ends to #150 / 300 /600

- Available for working pressure up to 40 bar and Differential Pressure up to 32 Bar

Clean Stream Trap

clean Steam is a purest form of available steam whose condensate should meet all the parameters of Water for Injection (WFI). In general terms it is defined as the steam which is free from all chemicals & biological impurities.

Application :

- Water for Injection System sterilization

- Fermenter sterilization

- CIP/SIP system condensate drainage

- Sterilization of process vessels and pipes

- Culinary systems

- Humidifiers

- Steam barriers (Blocks & Bleed System)

Inverted Bucket Traps

Steam used for secondary heating like Coils, vessels, heat exchangers etc, generate a lot of condensate post heat transfer. This large quantity condensate can handle by the Inverted Bucket Trap.This condensate has a substantial heat component with cost tagged to it. Also this is treated and pure water and can be used as Feed water for the Boiler, saving the cost of heating, Water Bill and Treatment chemicals.

Therefore it makes sense to recycle / reuse this condensate. This function is also done by the Inverted Bucket Trap, which works on the principle of Buoyancy, [densities difference of Water and Steam].The rising in condensate level fills and envelopes the Bucket causing it to sink which open the mechanically linked valve and discharges the condensate, and reverse, when the level of condensate drops Steam enters the bucket, causes the flotation of the Bucket which close the valve and stops condensate discharge & traps the steam.

- MOC: CF8M

- Available in Sizes: 15 mm – 25 mm

- End connections: Universal connection to be mounted on ITVS

- Available for working pressure up to 40 bar and Differential Pressures up to 32 Bar

Thermostatic Steam Traps

This trap works on the difference in Enthalpy of Steam and Condensate. A capsule attached to a Bellow filled with precise amount of a Hydrocarbon, Expands and contracts in response to the rising/lowering of Enthalpy. Thereby shutting and opening the valve. Condensate has lower Enthalpy, causing the bellow to contract and the seat to retract which opens the valve and allow discharge of condensate. The reverse happens with the steam and its higher Enthalpy.

These traps used largely on Tracing lines or Tank Farms where steam is supplied to maintain Temp / viscosity of the Oil.

UKL Thermostatic trap has a unique Simple design, Minimum number of components and where the Bellow is enclosed and protected thus ensuring long life for the Bellows

- MOC: Forged Carbon Steel and Stainless steel.

- Sizes: 15 mm – 25 mm

- End connections: Screwed/Socket weld ends.

- For Max Press up to 31 bar and Max. Temp 300Deg.C.